Step‑by‑Step Guide to Sourcing Injection Molding in China

So, the big meeting just wrapped up. your new product has been approved, time is pressing, and funding is, to put it mildly, limited. Then a voice—perhaps your manager or the CFO—drops the line that gives every project manager a shock: “We should look at sourcing this from China.”

Of course, you acknowledge. It makes sense on paper. The potential savings can be massive. Yet your thoughts are already spinning. You’ve heard the stories, haven’t you? The nightmare of defective parts, opaque communication, and delayed, off-spec shipments. It’s like balancing on a tightrope between a massive cost advantage and project disaster.

But here’s the catch. Procuring China injection molding needn’t be a roll of the dice. It’s simply another project with clear steps. And as with any project, success depends on your methodology. It isn’t about the cheapest offer but about choosing the right supplier and running the process transparently. Disregard those scary tales. Let’s go through a step-by-step guide to succeed.

Step One: Do Your Homework

Before you even whisper the word “supplier” or open a browser tab to Alibaba, you need to get your own house in order. Honestly, more than half of all overseas manufacturing problems start right here, with a weak or incomplete information package. You cannot expect overseas partners to interpret your unspoken requirements. A vague RFQ is like telling a contractor to bid on “a house.” You’ll get wildly varied quotes that are useless.

Your RFQ should be bulletproof—clear, detailed, and unambiguous. It’s the cornerstone of your entire effort.

What belongs in your RFQ?

First, your 3D CAD files. They cannot be skipped. Provide files in common formats (e.g., STEP, IGS) to prevent import issues. This serves as the definitive part geometry reference.

Yet 3D models don’t cover everything. Include precise 2D engineering drawings. Here you specify what 3D can’t show. Examples include tolerances (e.g., ‘25.00±0.05 mm’), material grade, surface finish requirements, and functional callouts. If a specific surface needs to be perfectly smooth for a seal, or a particular hole diameter is vital for an assembly, your 2D drawing needs to shout it from the rooftops.

Next up, material. Avoid generic terms like “Plastic.” Nor just “ABS.” Be specific. Call out SABIC Cycolac MG38 (black), for example. Why? Because there are thousands of plastic variations. Naming the precise grade locks in the mechanical, thermal, and aesthetic properties you need with plastic mold injection.

Your supplier might propose substitutes, but you must set the baseline.

Finally, include the business details. What’s your forecasted annual volume (EAU)? You must specify if it’s a 1K-part tool or a 1M-part production run. Tool style, cavity count, and unit cost are volume-driven.

The Great Supplier Hunt

Now that your RFQ is pristine. now, who do you send it to? The internet has made the world smaller, but it’s also made it a lot noisier. Locating vendors is easy; vetting them is the real challenge.

Begin on popular marketplaces such as Alibaba or Made-in-China. These are great for casting a wide net and getting a feel for the landscape. Use them to build a shortlist, not the final list. You’ll want to quickly build a list of maybe 10 to 15 companies that look promising.

However, don’t end your search there. Think about engaging a sourcing agent. True, they charge a fee. But a reputable agent brings pre-screened factories. They are your person on the ground, navigating the language and cultural barriers. For a first-time project, this can be an invaluable safety net. Consider it timeline insurance.

Another classic method? Trade shows. If you can attend, shows such as Chinaplas transform sourcing. In-person meetings trump emails. Hold samples, talk shop, and gauge professionalism firsthand. Also, leverage the tried-and-true referral network. Tap your professional contacts. A recommendation from a trusted peer is often worth its weight in gold.

Sorting the Contenders from the Pretenders

After firing off that RFQ to a broad pool, estimates roll in. Some will be shockingly low, others surprisingly high. Now, sift through and shortlist 2–3 reliable candidates.

What’s the method? It blends technical checks with intuition.

First, look at their communication. Is their turnaround swift and concise? Is their English good enough for complex technical discussions? The true litmus: are they raising smart queries? A great supplier will review your RFQ and come back with thoughts. “Have you considered adding a draft angle here to improve ejection?” or “We see your tolerance requirement here; our CMM can verify that, but it will add to the inspection time. Is that acceptable?” That’s a huge positive sign. It shows they’re engaged and experienced. Anyone who simply agrees to all specs is a red flag.

Next, dig into their technical capabilities. Request their machine list. More importantly, ask for case studies of parts they’ve made that are similar to yours in size, complexity, or material. Don’t pick a micro-molding shop for large components.

Then comes the audit. You can’t skip this. As you vet staff, you must vet suppliers. You can either go yourself or, more practically, hire a third-party auditing firm in China to do it for you. They perform a one-day factory inspection. They authenticate the firm, review ISO credentials, evaluate machines, and survey operations. It’s a tiny cost for huge peace of mind.

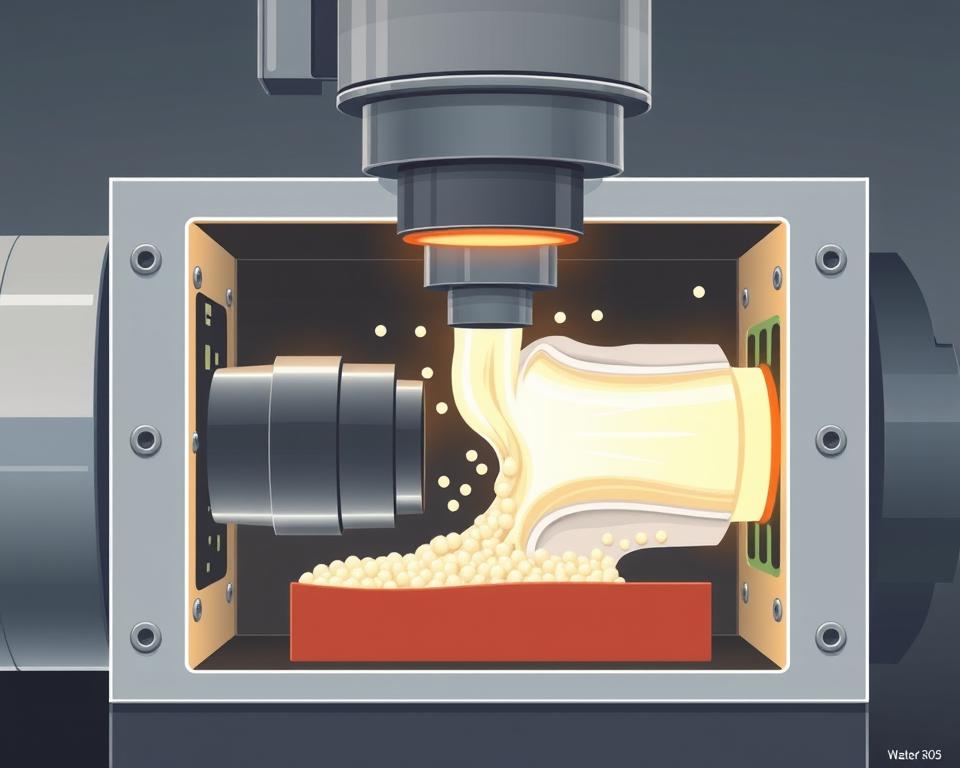

Transforming CAD into Real Parts

After picking your vendor, you’ve negotiated the price and payment terms—a common structure is 50% of the tooling cost upfront to begin work, and the final 50% after you approve the first samples. Now the real fun begins.

The first thing you should get back after sending your payment is a DFM report. DFM means Design for Manufacturability. It’s the engineering critique for moldability. The report calls out sink-risk zones, stress-causing corners, and draft angle gaps. A thorough DFM is a sign of a professional operation. It’s a two-way partnership. Together, you tweak the design for best manufacturability.

Once the DFM is approved, they’ll start cutting steel to make your injection mold tool. Weeks on, you receive the thrilling “T1 samples shipped” notification. These represent the first trial parts. They are your moment of truth.

Expect T1s to need tweaks. It’s par for the course. You’ll find minor defects, off-spec dimensions, or finish issues. You supply feedback, they tweak the tool, and T2 plastic mold in China samples follow. You may repeat this cycle a few times. The key for you, as the project manager, is to have this iteration loop built into your timeline from the start.

At last, you get the perfect shot. It matches all specs, has a pristine finish, and works as required. This becomes the “golden sample.” You ratify it, and it becomes the quality yardstick for production.

Completing the Sourcing Journey

Landing the golden sample is huge, yet the project continues. Next up: mass manufacturing. How can you keep part #10,000 matching your golden sample?

Put a strong QC process in place. This often involves a pre-shipment inspection. Bring in an external QC firm. For a few hundred dollars, they will go to the factory, randomly pull a statistically significant number of parts from your finished production run, and inspect them against your 2D drawing and the golden sample. They’ll send you a detailed report with photos and measurements. Once you sign off, you greenlight shipping and the last payment. This step saves you from a container of rejects.

Finally, think about logistics. Clarify your Incoterms. Is your price FOB (Free On Board), meaning the supplier’s responsibility ends when the goods are loaded onto the ship in China? Or EXW, where you handle everything from their gate? Your Incoterm selection drives landed expenses.

Overseas sourcing is a marathon. It’s about building a relationship with your supplier. See them as collaborators, not vendors. Clear communication, mutual respect, and a solid process are your keys to success. It’s a challenging project, no doubt. But with this framework, it’s one you can absolutely nail, delivering the cost savings everyone wants without sacrificing your sanity—or the quality of your product. You’ve got this.